Our system is portable and there’s absolutely no connection made with welding. It can be disassembled and assembled in another place if wanted.

Our system is portable and there’s absolutely no connection made with welding. It can be disassembled and assembled in another place if wanted.

DISMANTLED SYSTEM FEATURES:

Our system has a

portable feature and absolutely no connection is made with

welding. It can be disassembled and assembled in another

place if wanted.

There are no welded joints during assembly.

We make the installation with interlocking method.

Disassembled and reusable tribunes have been designed to

be very fast to install and detachable, and no wielding

required.

During the installation of the system, no consumables are

used such as welding, rivets, nuts or bolts etc. The whole

system is connected by interlocking method.

Bolt nuts and washers will be used only in the system

assembly of the front, side and rear railings and the

staircase exit railings.

In the system, we use carrier leaf springs, diagonal

connecting rods, connection apparatus and riser elements.

The vertical pendulum feet are used for the elevation of

the portable tribune system in the rear.

Materials such as concrete mosaic, heavy steel, which

weighs down the system, are definitely not used.

The materials to be used are light and portable due to the

disassembling nature of the system.

The frame of the system is made of hot roll-formed square

and rectangular profiles and welded industrial pipes.

These materials used as structural steel are St.37 and DIN

2394 (EN 10305-3: 2004) and DIN 2395 (EN 10219-2-1997)

standards compatible.

The manufacture of the parts will be made with gas welding

and CO2 is used as protective gas. The method of gas

welding is according to TS 5618 EN 440 -DIN 8559 – AWS 5,

18, BS EN 288 part 3 1988 and TS 5618 EN 440 standards.

FEATURE: CAN BE INSTALLED FOR ANY FLOOR:

There is no need

for any special floor covering during the installation of

the system.

It can be installed on any leveled floor.

It can be easily adapted in the field with different slope

soil structure.

In addition, the adjustment screws used to prevent the

floor faults also prevent the legs of the tribune from

sinking on unstable ground.

SEATING SECTION AND PVC SEATS

The height of

the seating section, the height and width of the risers

vary according to the project.

Seat height is 45 cm.

Different alternatives depending on the project are

offered in the seats to be used in the system.

WALKWAYS:

Wood to be used

as a platform flooring material is 12mm-thick, waterproof

and resistant to high load, moisture, dirt, acid, damp,

sweet and salt water. (Different alternatives can be

offered as per our customers’ request.)

The adhesive product to be used is resistant to water and

all weather conditions. Adhesive is selected according to

EN 3142. The approximate density of the wood material to

be used shall be gross 710 kg/m3 and the products that

comply with ISO-9001 and ISO-14001 are selected.

The width and height of the walkways vary depending on the

project.

The walkway substructure consists of a minimum of 3 box

profiles.

The walkways are interlocked to the system and the welding

method is not used.

TRIBUNE RAILINGS:

The sections of the tribune that are higher than the ground will be secured by the railing system.

LOAD-BEARING SYSTEM COATING:

All steel

construction system is covered with hot dip galvanizing

method. The steel construction that is coated with this

method increases the protection against corrosion to a

minimum of 15 years.

Hot dip galvanizing shall comply with TS 914 EN ISO 1461

(E), DIN EN 1461 Standards.

SAFETY OF THE SYSTEM AFTER INSTALLATION:

When the steel

construction parts of the removable tribune are assembled

to each other, the system is continued to be mounted in

one direction and the whole system is repeated to the end

of the tribune so that no part can be removed. It

eliminates the possibility of theft and sabotage.

This locking system makes the turbine’s load, static and

dynamic loads safe and durable to ensure the safety of the

spectators.

CAUTIONS:

Tribune manufacturing is subject to an significant static and dynamic load as it will carry many people on it at the same time. Design, manufacturing and installation must be very careful.

Therefore;

The static

calculations of the projects must be approved by a

technical university with a competency of static reports.

It should be taken into consideration that the system

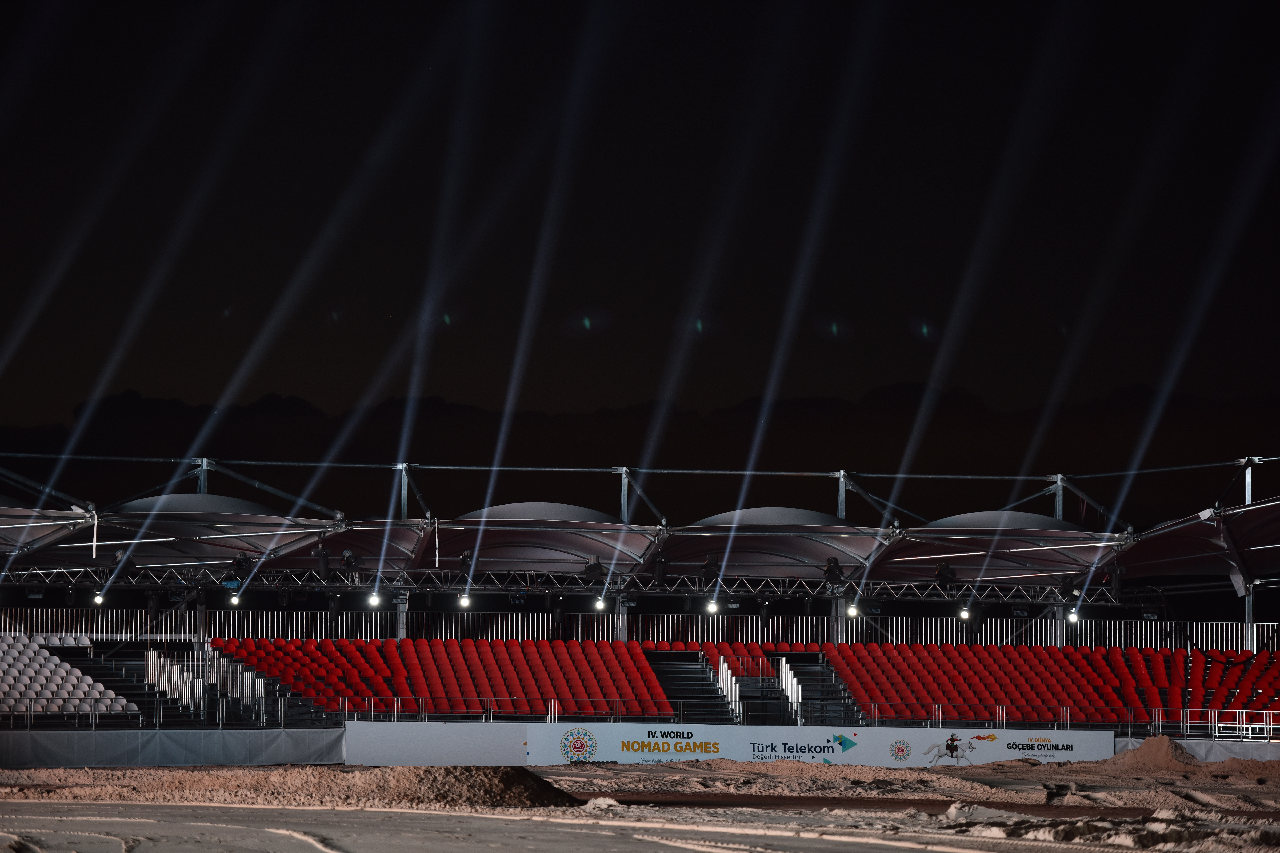

should have been used in an international organization,

been tested for the safety, and be an ergonomic,

functional, long-lasting and economical solution according

to tests on-site.

It is important that the contractor firm, which will carry

out the production and assembly of the project, is a

specialized manufacturer. The contractor firm must have

manufacturer certificates for portable stand, telescopic

stand and a mobile tribune from the chamber of industry

and commerce.

The contractor firm, which will carry out the production

and assembly of the project, must have a capacity report

and an industrial registry certificate issued by the

chamber of industry and commerce in the name of the

contractor.

The contractor must have an equivalent work certificate.

(From government institutions)The contractor must have ISO

and CE certificate.